Thought of the Day - February 4 - Container Shortage

- Cliff Fraser

- Feb 4, 2021

- 2 min read

Updated: Jul 30, 2021

No, I am not talking about packaging shortages affecting vaccine supply, I am talking about shipping containers - you know, those big steel boxes on container ships that are infamous for going overboard.

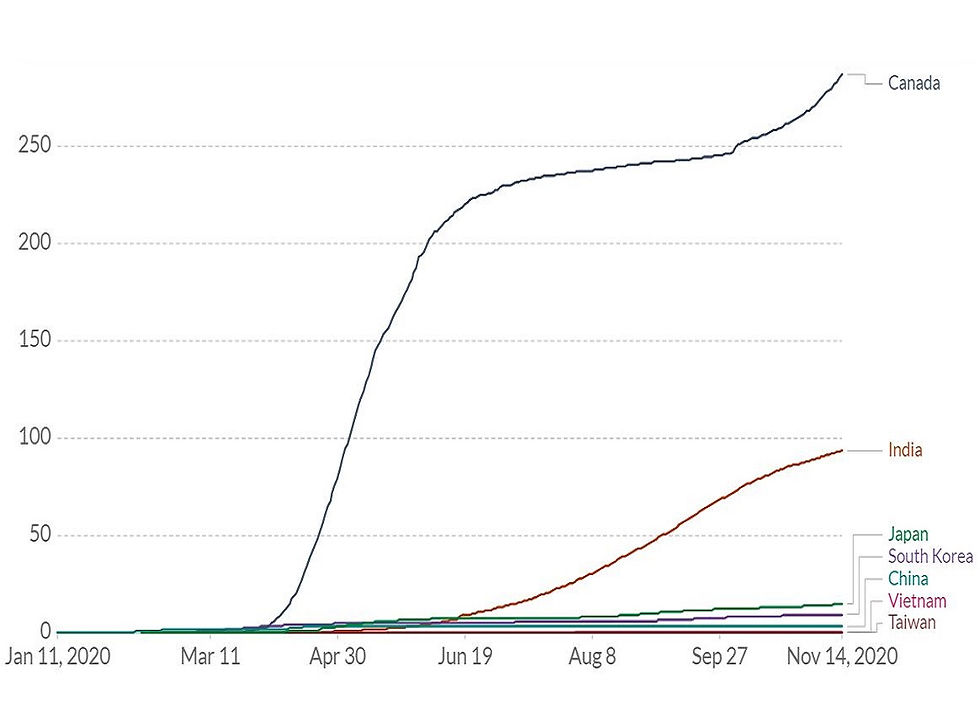

This has been talked about for some months now. With the rapid economic recovery in Asia - remember the growing economies that clamped down on the domestic spread of COVID ( Thought of the Day - November 15 - By the Numbers ) - there is now a critical shortage of containers in Asia.

Headlines now read:

"Shipping costs have skyrocketed as desperate companies wait weeks for containers and pay premium rates to get them, according to industry watchers.";

"Ikea’s Singapore operations called it a “global transport crisis” and estimates 850 of its 8,500 products are affected by shipment delays.";

"Chinese tech giant Alibaba’s logistic arm Cainiao launched a container booking service last week in response to the global shortage."

In December, spot freight rates were 264% higher for the Asia-to-North-Europe route, compared with a year ago, and the route from Asia-to-West-Coast -U.S., rates are up 145% year over year.

Compared with last March’s low prices, rates from China to the U.S. and Europe have surged 300%, spot rates are up to about $6,000 per container compared with the usual price of $1,200. Early figures from January see this trend accelerating on some routes.

This is all evidence of a significant trade imbalance. Asian economies, especially China, have bounced back faster as the virus situation within its borders was basically under control by the second quarter of last year. With western world economies still on hold, 3 out of 4 containers from the U.S. to Asia are “going back empty". A similar crisis is happening in some European countries, such as Germany, Austria and Hungary, as carriers redirect containers to the East as quickly as possible.

Making matters worse, orders for new containers were largely cancelled during the first half of 2020 as most of the world went into lockdown. But even the race to build more containers has been hobbled by delays as the pandemic has also hit the supply of steel and lumber needed to build them.

The shortage is further exacerbated by limited air freight capacity. Some high-value items that would normally be delivered by air, now have to use containers via sea instead, as international flight volumes have plunged due to virus and travel restrictions. So what does this really mean? The "container crisis" affects all companies that need to ship goods. The related costs need to be absorbed by retailers or passed on to customers. In short, as well as the earlier news that produce, and especially meat, will see significant price increases in 2021 ( Thought of the Day - December 20 - By the Numbers ), it may not be long before manufactured consumer goods could also see the same.

Cheers

Cliff

Comments